Chini Mills Limited (BCML),one of the largest integrated sugar mill complexes in India sincerely advocates sustainability through its eco-friendly product basket coupled with a host of sustainable manufacturing practices, actively devised by the Company. Under the abled stewardship of distinct leaders, BCML has diversified its offerings over the years. From being a leading sugar manufacturer to venturing into business lines like that of cogeneration and distillery, BCML has consciously streamlined its efforts towards carving a sustainable future. Recently, the Company announced its upcoming PLA-manufacturing venture through which it aims to responsibly intervene into the market of Single-Use-Plastics and drive a sustainable switch.

The Company’s futuristic vision translates into its core operational philosophy wherein it aims to generate more from less. BCML’s journey in the line of sustainability is defined by 6 paramount concepts – Integrated, Zero Liquid Discharge, Financial Prudence, Biofuel, Cane Competence and Digitalisation.

Through seamless integration, BCML has been able to generate maximumvalue from a stick of cane on one hand and ensure enhanced return on employed capital on the other. While the process of integration possesses notable environmental benefits but also boost financial value for all stakeholders. Expansion of BCML’s distillery capacity has been one of the primary factors which led to a significantly lower need of borrowed funds to grow the business. While biofuel has significantly transformed the destiny of BCML, it was also amongst the first companies to respond to the National Biofuel Policy of 2018 through notable investments directed towards the distillery business. From 360 KLPD in 2017-18 to a whopping capacity of 1050 KLPD, BCML has rapidly ramped up its distillery capacity.

BCML not only actively invests to enhance the quality and productivity of the primary raw material i.e. sugarcane but also collaborates with advanced cane research institutes to introduce superior cane alternatives. Being one among the first sugar companies to implement the power of digitalisation, it helped the Company to centralize data around common platforms and thereby led to undertaking well-informed decisions.

From successfully graduating all its distilleries to zero liquid discharge, installation of incineration boilers in sugar manufacturing plants, before the same was mandated to making proactive investments in the construction of state-of-art units to recycle and reduce condensate water and many more, BCML’s futuristic approach can be mapped through the notable steps proactively undertaken by the Company.

The renewable by-products manufactured by BCML, significantly contributes to replace the use of finite fossil fuels with biodegradable alternatives. The Company’s latest investment in Poly Lactic Acid manufacturing stands testimony to itsrelentless efforts in the line of advocating sustainable switches.With an estimated investment of INR 2,000 crore, BCML aims to tap into the market of bioplastic production. Through this venture, the leading sugar manufacturer aims to optimally instrumentalize sugar to produce PLA, and thereby significantly reduce the consumption of SUPs. Derived from a crop as widely grown in the country, as sugarcane, PLA bioplastic is not only an environment-friendly alternative but also inhibits properties which enables seamlessly replacement of fossil-fuel based plastics, thereby reducing the country’s energy dependence. To cut down major infrastructural expenses and leverage the existing resources, the Company has planned to establish the upcoming project on a “greenfield site” adjacent to an existing sugar plant.

Through strategic utilization of the by-products, BCML has successfully established a circular economy within the Company. Led by industry statesmen, BCML identified the potential of biofuels andenvisioned arise in thenecessity to attain energy independence in the future, therebymade sizeable investments and ventured into the business of distillery and cogeneration, back in 1995. To enhance its contribution towards India’s biofuel production, BCML undertook a decisive step wherein it dedicated its Maizapur unit to solely produce ethanol.

Precisely, BCML’s dedicated efforts havehelped establish a seamless integrated model of operations wherein one end product serves as the raw material for the production of another. Hence the operational philosophy devised by the Company speaks volumes of its vision of securing an energy independent tomorrow.

****************************

BC Jindal Group Wins 150 MW Round-The-Clock Tender from Solar Energy Corporation of India Limited

BC Jindal Group Wins 150 MW Round-The-Clock Tender from Solar Energy Corporation of India Limited  ORSL and SSS-NIBE Launch SEED/Culture Consortium Based Pilot Biomethanation Plant in Solapur, Maharashtra

ORSL and SSS-NIBE Launch SEED/Culture Consortium Based Pilot Biomethanation Plant in Solapur, Maharashtra  BASF launches two innovations: Valexio® & Mibelya® that will help support Indian rice growers achieve better and higher quality yields

BASF launches two innovations: Valexio® & Mibelya® that will help support Indian rice growers achieve better and higher quality yields  Blooming from the Clasp of Darkness Sachin Tendulkar Foundation (STF) and Mann Deshi Foundation Transforming Dantewada, One Maidan at a Time

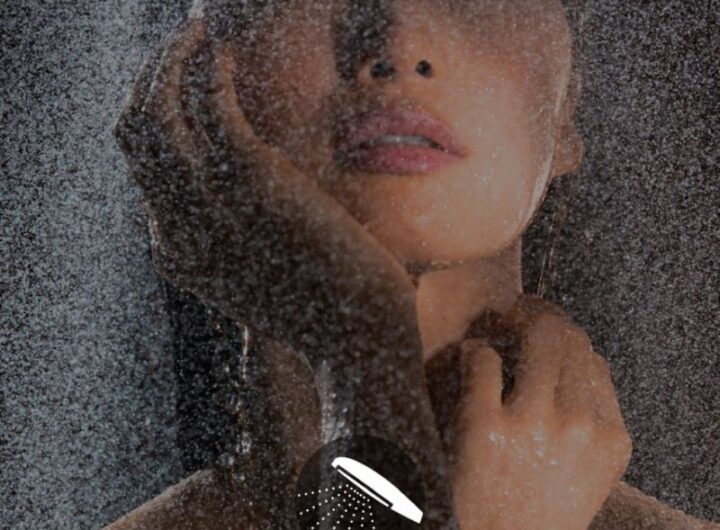

Blooming from the Clasp of Darkness Sachin Tendulkar Foundation (STF) and Mann Deshi Foundation Transforming Dantewada, One Maidan at a Time  TOTO India Introduces New Variant of shower – Mist Spa, Enhancing Daily Wellness with Advanced Microbubble Technology

TOTO India Introduces New Variant of shower – Mist Spa, Enhancing Daily Wellness with Advanced Microbubble Technology